Biomanufacturing

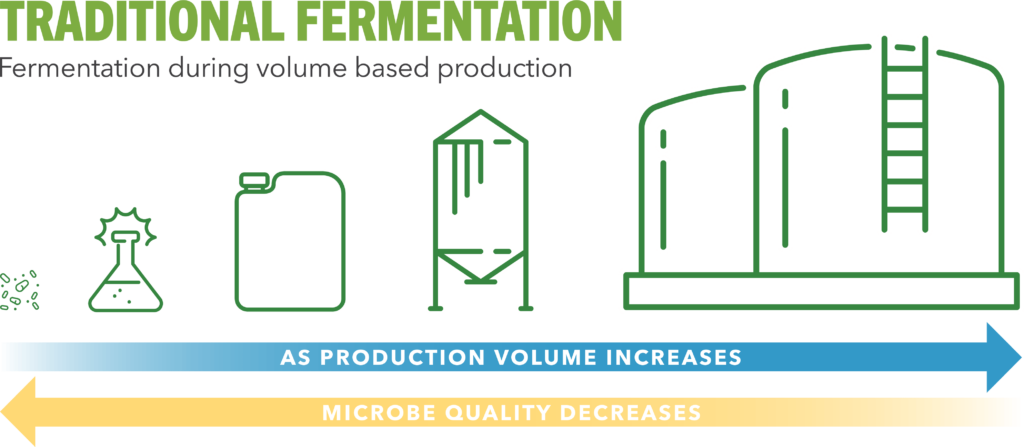

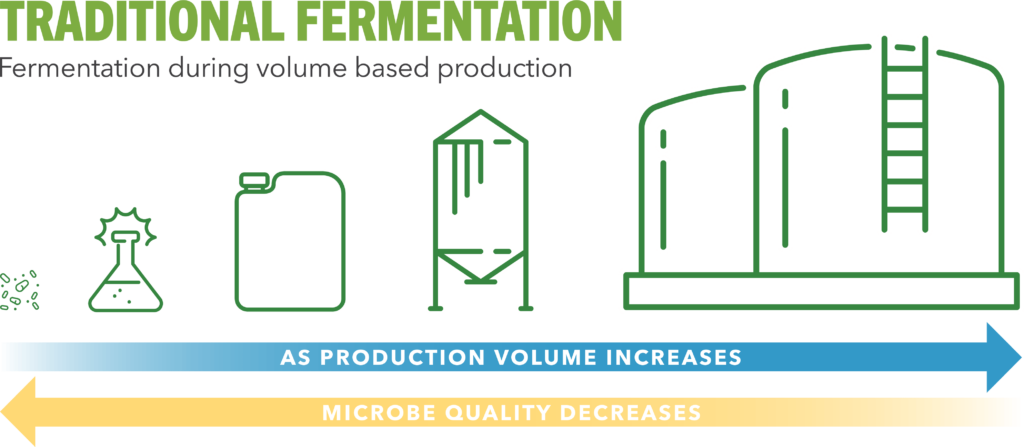

Traditional production is not ideal for living microbes.

Unlike traditional production and delivery methods, 3Bar Biologics’ innovative, modular process reduces CapEx, increases output, de-risks the microbe production journey, and accelerates speed-to-market—increasing manufacturing flexibility, production agility, efficiency, and cost-effectiveness.

CUSTOMER CHALLENGES

Large-vessel fermentation is costly, difficult to ensure consistency, and often subject to quality pitfalls. Global distribution is logistically challenging. And contamination is inevitable.

3Bar Biologics Solutions

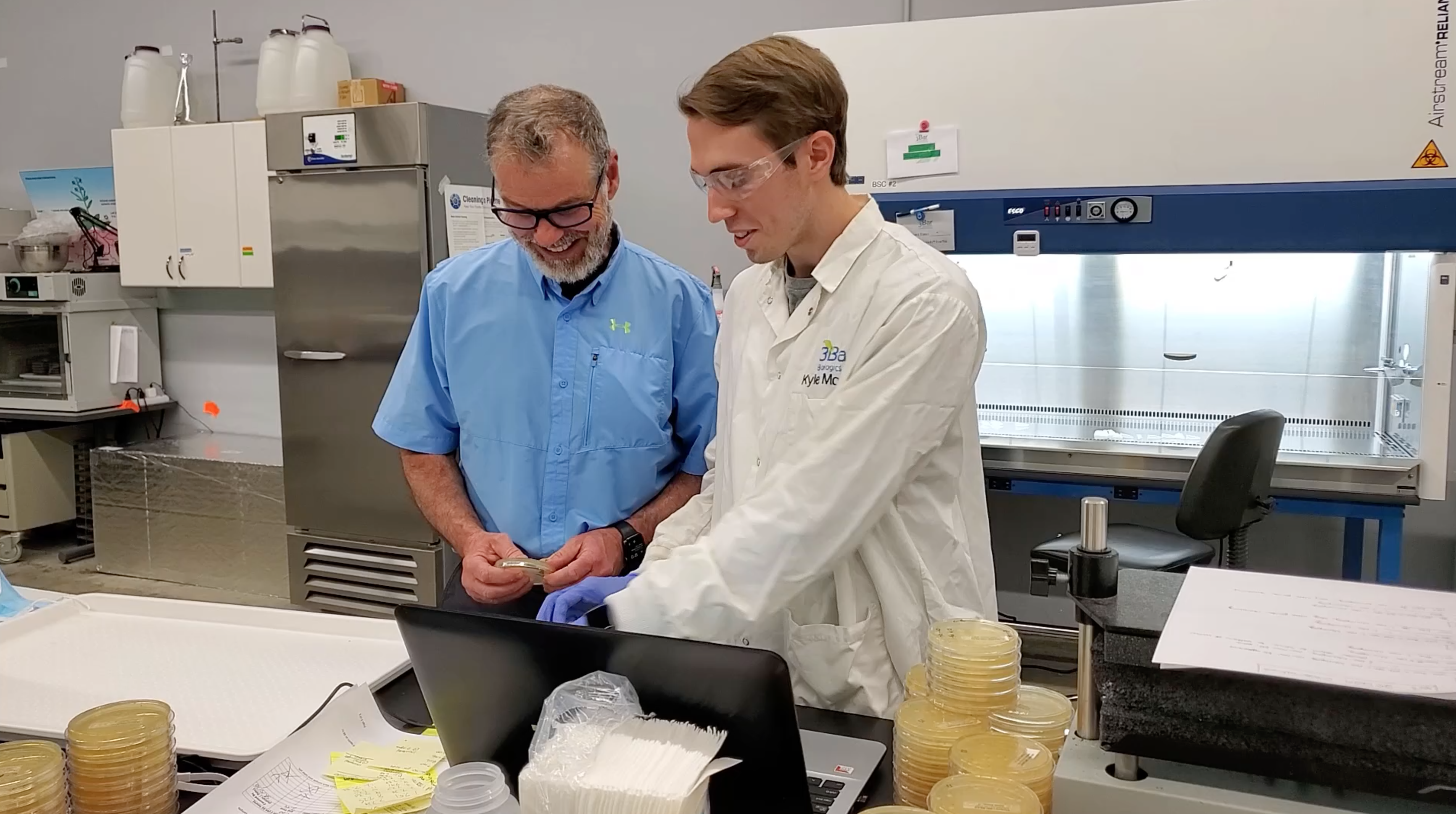

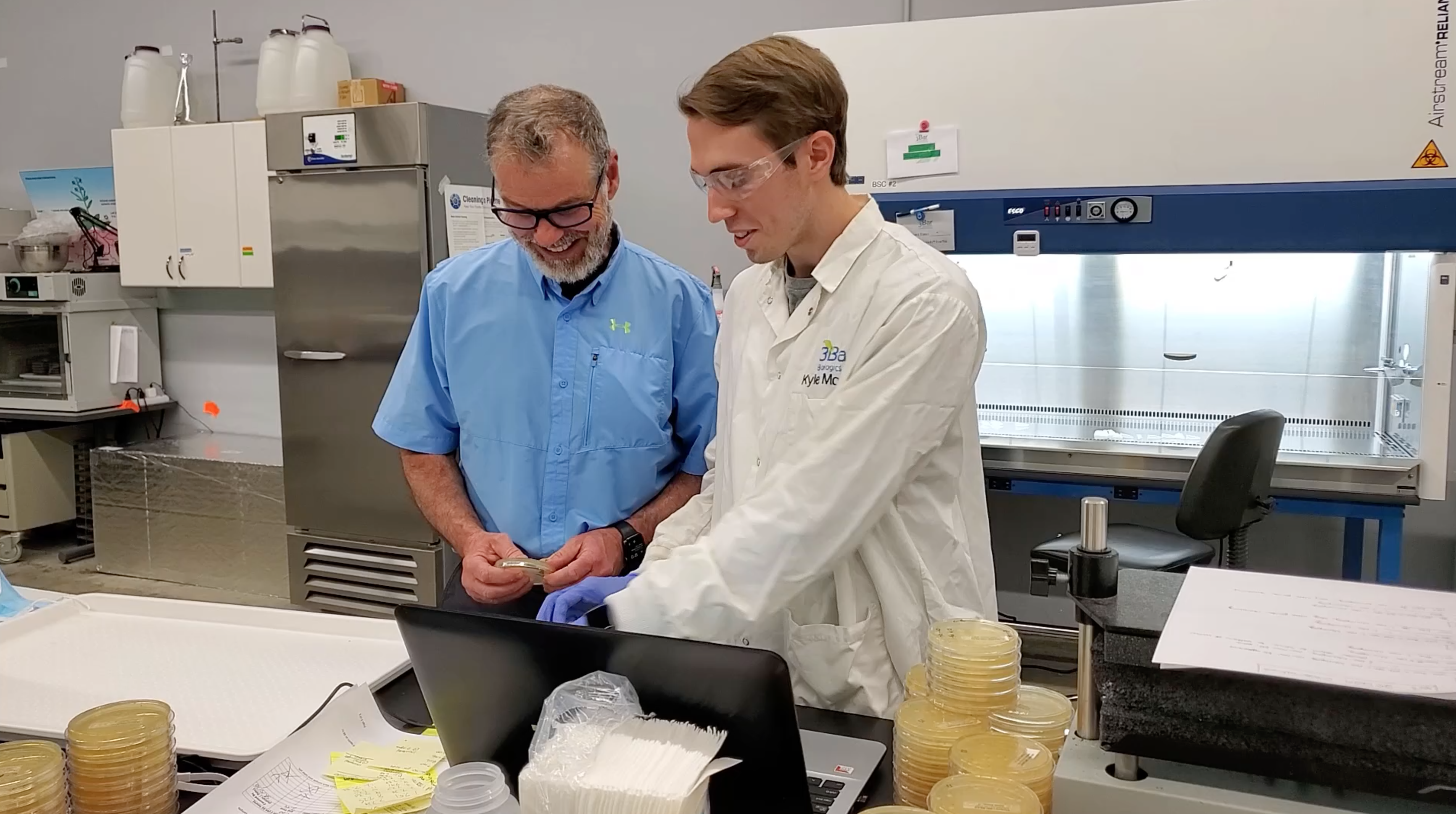

We efficiently and cost-effectively manufacture your microbes, increase their shelf life, and help you maintain your label claims—with a repeatable innovative approach.

In production, each microbe gets a self-contained, dedicated module, leading to a reliable manufacturing process, production flexibility, and cost-effectiveness. And we do this in a repeatable and consistent process each time with zero contaminants.

A biomanufacturing “module”:

- Dedicated to your microbe and its productization

- Liquid filling can be located regionally near distribution areas, reducing costs

- Produces up to 140,000L/month or over 1M acres/month

- Just-in-Time assembly results in minimal lead times and early quality control checks

Benefits of our modular approach:

Facilitates global distribution

Saves energy

Scales easily to meet demand

Reduces water use

Accomodates a wide range of microbes

Eliminates contamination

Manufacturing capacity currently available.

Bio-Supply Chain Solutions

Increased demand? No problem.

Unlike traditional manufacturing and fermentation processes used today, our approach shifts the quality control and lead-time risk to earlier in the supply chain. That means forecasts can be flexible and orders can be placed closer to application.

Our modular, unitized production process—in which dry microbe formulation is created in advance, and later assembled with liquid—scales easily to match demand, eliminating capacity crunch and minimizing lead times.